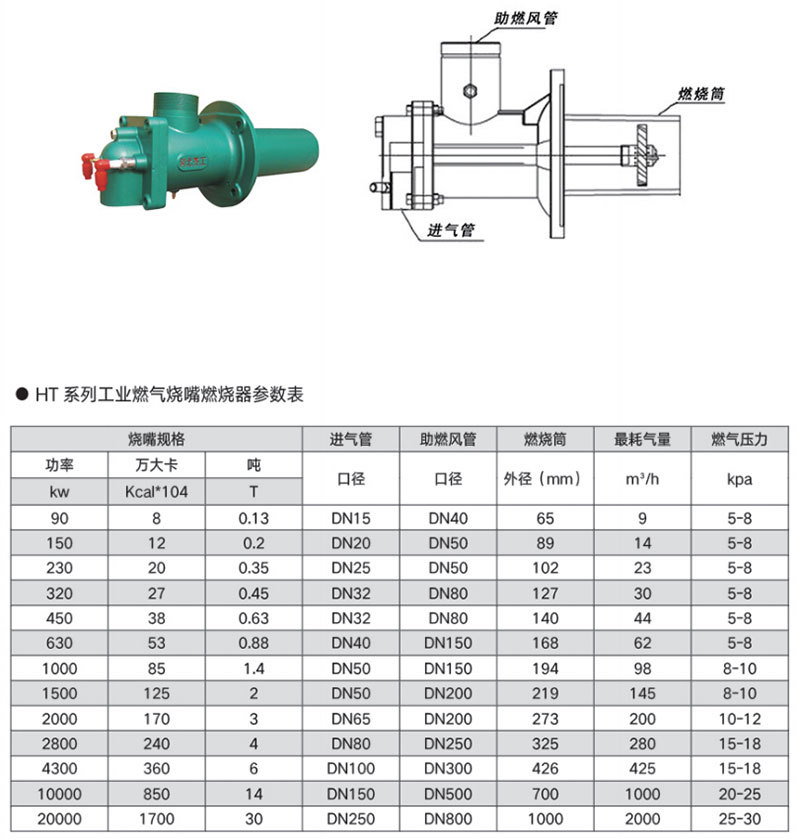

HTQ natural gas burner

keyword:

Category:

The concept and classification of natural gas burners: Natural gas burners are commonly used in industrial kilns and chemical heating devices, and some are also commonly referred to as natural gas burners.

1、 Burner classification:

According to the pressure of natural gas before the burner:

Low pressure natural gas burner: The natural gas pressure is below 5kpa.

High and medium pressure natural gas burner: The natural gas pressure is above 5kpal.

According to the shape and type of the flame:

Straight flame burner: also known as long flame burner, with a longer flame, commonly used in kilns, such as heat treatment kilns and container annealing furnaces.

Short flame burner: The flame is short and rigid.

Flat flame burner: The flame is sprayed out in the shape of a disc that is tightly attached to the furnace wall or evenly extended around the furnace top. Suitable for: shell baking furnace, forging heating furnace.

Classified by air supply method:

Self suction burner: The burner does not require the use of external force for air distribution, and has its own Venturi structure, which can suck in external air. Generally, the power of the burner is small.

Air distribution burner: combustion supporting air is forced by blower, and the fan is usually a high-pressure centrifugal fan.

According to the air fuel mixing method:

Diffusion burner: The air required for combustion is pre mixed with natural gas.

Atmospheric burner: also known as semi premixed natural gas burner. The air required for combustion is mixed with natural gas.

Fully premixed burner: The air required for combustion is pre mixed with natural gas, and is generally used on flameless combustion type burners.

Special function classification: It can be divided into various new energy-saving burners, such as regenerative burners, radiation tube burners, adjustable temperature burners, and low nitrogen burners.

2、 Natural gas burner is a commonly used combustion device in industrial kilns. The performance of natural gas burner will greatly affect the quality of products. A reasonable and efficient natural burner should be able to meet the combustion, heating, and product process requirements of the kiln.

3、 Combustion process: The combustion of natural gas is generally divided into three processes: the mixing of gas and air; the heating and ignition of the mixed gas; Combustion of mixed gases. The condition for flame stability is that the flame propagation speed and the flow velocity of the combustible gas mixture are equal in magnitude and opposite in direction.

Stable combustion: The mixing speed of gas and air exceeds the flame propagation speed, causing the flame to leave the stable point. Tempering of the burner: The mixing speed of gas and air is less than the flame propagation speed, and the flame sprays into the interior of the burner. The detachment and tempering of the burner are not the ideal combustion state of the burner, and the burner mostly adopts a flame stabilizing disc structure to achieve good state.

Contact Us

Address: No. 51 Jinma Road, Yuhua District, Shijiazhuang City, Hebei Province, West America Wuzhou MOCO1403

Related products

Get product quotes for free

Our staff will contact you within 24 hours (working days). If you need any other services, please feel free to call the service hotline:+86-0311-87777707