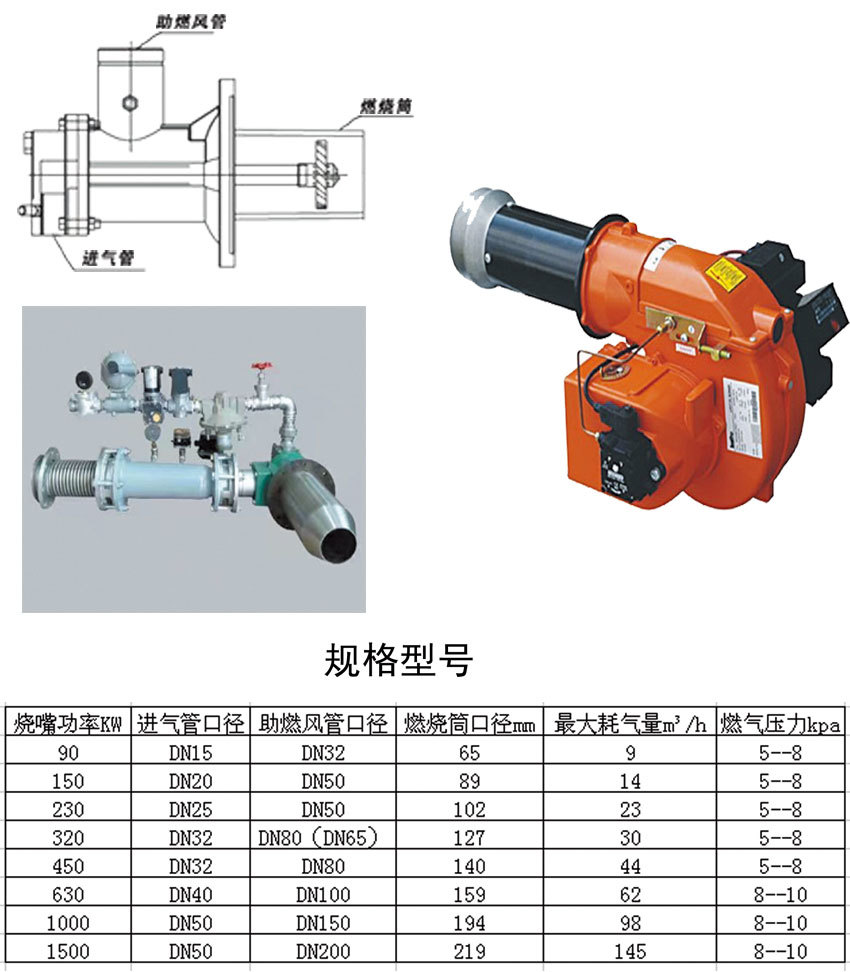

Industrial furnace burner (burner)

keyword:

Category:

Natural gas industrial furnaces play an important role in industrial production, and the gas burner, as a combustion device in industrial furnaces, is crucial for the production of the entire furnace.

Applicable industries:

Metallurgy, chemical engineering, ceramics, glass, refractory materials, building materials, papermaking, pharmaceuticals, etc.

Applicable kiln type:

Industrial kilns such as tunnel kilns, roller kilns, push plate kilns, heating furnaces, quenching furnaces, annealing furnaces, hot air furnaces, boilers, etc.

The burner used in this system belongs to a low-pressure high-speed burner, which comes with dual electrodes (ignition electrode and detection electrode). A stable flame disc is set inside the burner, effectively avoiding the problem of easy detachment and flame separation caused by natural gas fuel itself. The adjustment ratio can reach 1:10, and the high-temperature flue gas can reach 80 meters per second. Effectively improve the heat utilization rate of the furnace.

This combustion system adopts automatic ignition, flameout protection, and automatic temperature control methods, reducing the requirements for workers' operating skills, making it safe, reliable, and cost-effective. The system is composed of burner, ignition device, solenoid valve, flame detector, manual valve, proportional valve and actuator. Its operation process is: manually purge the furnace before ignition → ignite the igniter → open the solenoid valve → fuel gas is ejected and ignited → flame is found by the flame detector → solenoid valve continues to open → flame burns normally → instrument temperature control and temperature adjustment according to product needs.

Ignition device: The automatic ignition device consists of a burner controller and an ignition electrode. The ignition electrode generates an arc through high-voltage discharge on the ignition column or the inner wall of the burner to ignite the gas. The burner controller is equipped with an ignition transformer

Flame detection device: the system uses the ion bar equipped with the burner to detect. The flame detector sends a signal to close the solenoid valve and stop the burner when the gas is not ignited or when flame separation and flame off occur after ignition.

Flame out protection device: the flame out protection is jointly completed by the flame detector and the solenoid valve. The ion bar detection is used for flame detection. The conductivity of the flame, the presence of the flame, and the signal generation are used to amplify the signal by the burner controller to make the solenoid valve connected. Conversely, the solenoid valve is automatically closed in case of power failure and other emergencies to ensure production safety.

This system adopts continuous proportional adjustment combustion, with actuators controlling the air volume and adjusting the gas size through proportional valves to achieve air fuel proportional combustion. Each burner is equipped with a gas solenoid valve, and each burner is equipped with an independent igniter, which has automatic ignition, flame detection, and flameout alarm functions.

Previous page

Next page

Contact Us

Address: No. 51 Jinma Road, Yuhua District, Shijiazhuang City, Hebei Province, West America Wuzhou MOCO1403

Related products

Get product quotes for free

Our staff will contact you within 24 hours (working days). If you need any other services, please feel free to call the service hotline:+86-0311-87777707